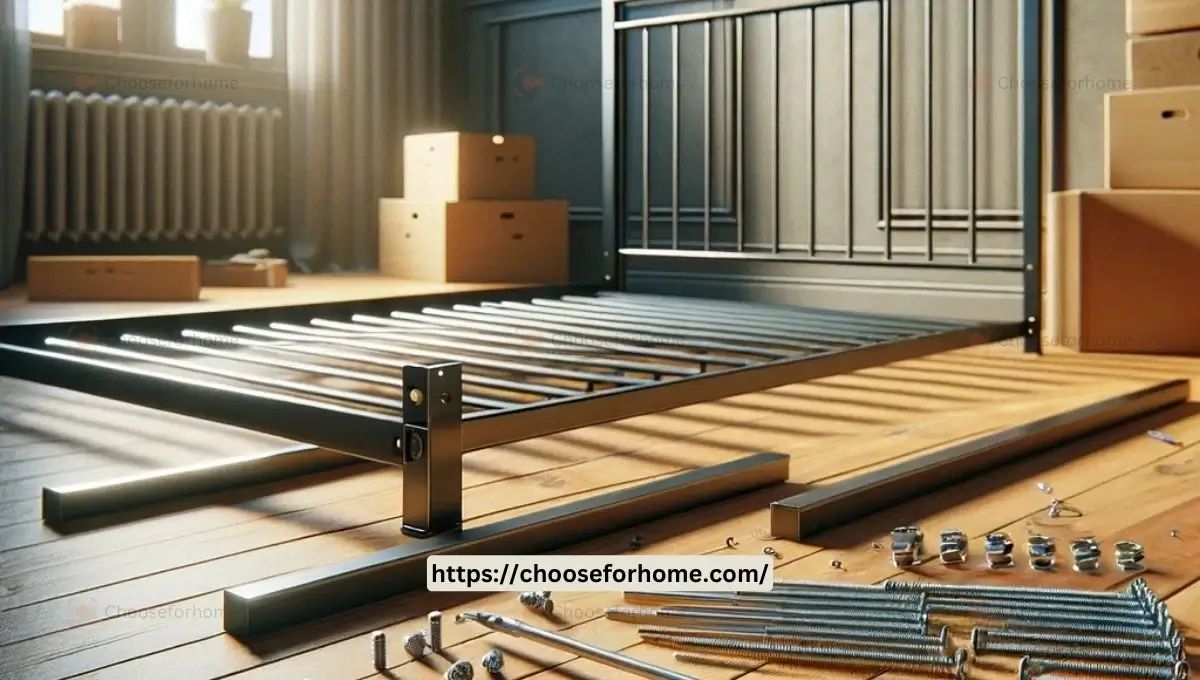

Fixing a broken metal bed frame is quite challenging. Lots of people think it’s just easier to get a new bed then fixing a metal bed frame. However, with the right tools and a little bit of know-how to fix a metal bed frame can be an easy DIY project that prolongs your bed’s life and saves money.

This comprehensive guide is designed to help you understand the common issues that lead to damage, identify the tools and materials you’ll need, and provide step-by-step instructions on how to fix a broken metal bed frame effectively. Whether you’re dealing with bent rails, loose joints, or broken slats, our aim is to empower you with the knowledge and confidence to tackle the repair yourself.

Understand The Fundamentals Of Your Bed Frame

Different Types of Metal Bed Frames

Metal bed frames are available in a wide array of styles, including platform beds, designs with both headboards and footboards, bunk beds, and many others, offering versatility and durability for every bedroom. The specific type of metal bed frame you own can significantly impact the approach you take towards its repair.

For example, platform beds, which are known for their sturdy and minimalist design, frequently encounter issues with bent or broken slats due to the weight they bear. On the other hand, bed frames that include headboards and footboards can sometimes suffer from loose welds, requiring a different repair strategy to ensure stability and longevity.

Additionally, bunk beds, designed to save space while providing multiple sleeping areas, may need checks for joint integrity and overall frame strength to prevent accidents. Understanding the nuances of your bed frame’s design can help ensure you address any issues effectively, maintaining its functionality and appearance.

Identifying Common Weak Points

Most metal bed frames are prone to failure at specific points: the welds, the connections between different parts, or the center support beams. These critical areas bear the brunt of weight and stress, making them particularly vulnerable to breakage. Over time, the constant pressure and use can cause these points to weaken, leading to potential failure and the need for repair or replacement to ensure the bed frame remains safe and functional.

Materials Commonly Used in Metal Bed Frames

Common materials used in construction and fabrication include steel and wrought iron, each necessitating a unique approach for effective repair. Steel, for example, is a versatile material that can often be repaired through welding techniques, utilizing high heat to fuse the material back together.

On the other hand, wrought iron, known for its ornamental uses and historical significance, might require a more delicate and careful approach to repair, such as using specialized techniques that preserve its intricate designs without causing further damage.

Find Out The Damage Area Of The Metal Bed Frame

Identifying the exact damage location to fix a broken bed frame. Start by fully disassembling your bed frame, if possible, to inspect each component closely. For frames that cannot be completely taken apart, ensure you have clear access to all sides.

Use a bright light to meticulously examine the frame, paying special attention to the common weak points such as welds, joints, and support beams. Look for visible signs of damage, including cracks, rust, or bends. It’s also important to apply gentle pressure to various parts of the frame to identify any areas that may have become weakened but not yet visibly broken.

For areas that are painted or coated, check for chipping or flaking as these could indicate underlying issues. Documenting the damage by taking notes or photographs can help track the repair process and ensure no areas are overlooked.

Tools Needed for Assessment

For this particular step, you’ll find that a flashlight and a measuring tape become indispensable tools in your toolkit. Initiating with a thorough visual inspection using the flashlight will help you pinpoint both the location and the nature of the break with greater accuracy.

Following this, employing the measuring tape can aid in assessing the dimensions of the affected area for any necessary repairs. Moreover, conducting functionality tests is crucial as it can expose any underlying wobbling or stability concerns, ensuring that you’re fully aware of the extent of the issues at hand.

Supplies Need To Fix A Metal Bed Frame

Safety Gear

Before starting your metal bed frame repair project, it’s crucial to gather the right safety gear to protect yourself. Here’s a list of the essential safety items you’ll need:

- Safety Glasses: Protect your eyes from metal filings, dust, and any debris that might fly up while you’re working.

- Gloves: Wear a pair of thick gloves to safeguard your hands from sharp edges and hot surfaces, particularly if welding is involved.

- Ear Protection: If you’re using power tools, wearing ear protection can help prevent hearing damage from prolonged exposure to loud noises.

- Respiratory Mask: A mask is vital to prevent inhalation of any dust or fumes, especially important if you’re sanding metal or using any chemical agents.

- Protective Clothing: A long-sleeved shirt and long pants made of a thick, durable fabric can help prevent cuts and scrapes.

- Fire Extinguisher: Keep a fire extinguisher nearby if you’re doing any welding to quickly deal with any potential fires.

Tools And Repair Materials

Once you’ve assembled your safety gear, it’s time to gather the tools and materials needed for the repair. Here’s a comprehensive list to ensure you’re fully prepared:

- Welding Machine: Essential for fusing metal parts together. If you’re not experienced with welding, consider hiring a professional.

- Metal File: To smooth out any rough edges after welding or cutting.

- Hammer and Mallet: Useful for straightening bent parts of the frame.

- Adjustable Wrench: For tightening bolts and nuts that may have loosened over time.

- Screwdrivers: To adjust or remove any screws.

- Measuring Tape: For precise measurements, ensuring that any replacements or repairs fit perfectly.

- Metal Cutter: For removing severely damaged sections that require replacement.

- Replacement Parts: Such as bolts, nuts, screws, and metal slats or beams, depending on the specific repair requirements.

- High-Quality Metal Paint: To touch up any areas after repairs, providing a fresh look and preventing rust.

- Anti-Rust Treatment: To apply on the metal surfaces, safeguarding against future rust and wear.

- Clamps: To hold pieces in place while welding or fitting new parts.

Ensuring you have these tools and materials at hand before starting your repair will streamline the process, making it more efficient and effective.

Repair Methods Of Metal Bed Frame

For Minor Bends and Cracks

For minor bends and cracks in a metal bed frame, a methodical approach can restore the frame’s integrity and appearance. Begin by cleaning the affected area with a wire brush or sandpaper to remove rust, paint, and any debris, creating a smooth surface for repair.

For bends, use a hammer or mallet to gently straighten the bent sections. It’s crucial to do this slowly and carefully to avoid creating further damage. For small cracks, welding can be an effective solution. Using a welding machine set to the appropriate settings for the metal type, carefully weld the crack to seal it.

If you’re inexperienced with welding, consider seeking professional assistance to ensure a secure and safe repair. After welding, use a metal file to smooth down the welded area, followed by applying anti-rust treatment and paint to protect the repaired section from future corrosion. This process not only fixes the damage but also prolongs the lifespan of the bed frame.

For Broken Welds and Snapped Components

Repairing broken welds and snapped components on a metal bed frame requires a meticulous approach, combining precision and specific techniques to ensure durability and safety. Begin by removing any rust or debris from the broken areas using a wire brush, ensuring a clean surface for a strong weld.

If the component has snapped, align the pieces as closely as possible before proceeding. Use clamps to hold the pieces in place during the repair process. For broken welds, re-welding the joint is often the most effective solution. Set your welding machine to the correct settings for the frame’s metal type, and carefully weld the joint, ensuring full penetration for a strong bond.

For snapped components, if the break is clean, you can weld the pieces back together using the same technique. If the break is jagged or parts are missing, you may need to fabricate a new piece or source a replacement. After welding, inspect the repair to ensure it’s solid and there are no gaps in the weld.

Use a metal file to smooth any rough edges or excess material from the welding process. Applying an anti-rust treatment followed by a coat of high-quality metal paint not only helps to prevent future rust but also restores the aesthetic appeal of the frame.

Finally, reassemble the bed frame and conduct a thorough inspection to ensure stability and safety. If any doubt remains about the integrity of the repair, consult with a professional welder or metalworker to assess the frame’s safety for use.

Repair Considerations Based on Material

When approaching metal bed frame repairs, the material composition — whether it’s iron, steel, aluminum, or an alloy — significantly influences the repair method.

- Iron and steel frames, known for their strength and durability, often require welding for effective repair but demand attention to prevent overheating, which can cause warping. Preheating might be necessary for thicker sections to ensure a thorough weld without damaging the metal.

- Aluminum frames, lightweight and less prone to rust than iron or steel, necessitate a different approach due to aluminum’s higher thermal conductivity and lower melting point. Specialized aluminum welding techniques, such as TIG (Tungsten Inert Gas) welding, are preferred to avoid weakening the frame’s integrity.

- Alloys, being a mixture of metals, require knowledge of their primary components to select the correct welding method and filler material. For all materials, applying the appropriate anti-rust treatment post-repair is crucial to prolong the life of the frame. This tailored approach ensures that repairs are not only effective but also maintain the structural integrity and aesthetic value of the bed frame over time.

Reassemble And Reinforce The Metal Bed Frame

Once repairs are complete, the reassembly of your metal bed frame requires careful attention to detail and precision to ensure the longevity and safety of the repairs. Begin by methodically reattaching any components that were removed or replaced during the repair process.

Use the adjustable wrench and screwdrivers to securely fasten bolts, nuts, and screws, ensuring that all connections are tight and stable. This is the time to incorporate any reinforcement measures needed to bolster the frame’s structure. For areas that were welded, inspect the welds for any signs of weakness or cracks and consider applying a metal brace or splint over the welded area for added stability.

Additionally, if the frame design permits, adding extra slats or metal struts can significantly improve the bed’s weight distribution and overall sturdiness. Ensure that these additions are uniformly spaced and securely attached to the frame. After reassembly, conduct a comprehensive inspection of the bed frame to verify that all parts are correctly aligned and firmly connected.

Apply a final coat of high-quality metal paint and anti-rust treatment to any exposed or repaired areas, safeguarding your bed frame against future wear and ensuring a cohesive appearance. With these steps, your metal bed frame should be well-prepared to provide enduring support and comfort.

Conclusion

Repairing your metal bed frame is a cost-effective way to extend its life and improve your home. Whether you’re tackling a minor bend or a complete break, the key is to assess the damage carefully, gather the right tools and materials, and follow safety precautions.

With a bit of effort, your bed frame can be as good as new, serving as a proud testament to your DIY skills. By saving money and contributing to a more sustainable living environment, fixing your metal bed frame becomes not just a necessity but a meaningful project. Remember, the key to a successful repair is assessing the damage accurately, choosing the right repair method, and not being afraid to seek professional help when needed.